In a previous project, I showed how to use recycled aluminum to cast useful parts using lost PLA casting. Since then, I played the game “Among Us”. I wonder if I can use this same technique to create an aluminum crewmate. Seems straightforward enough. Are you ready to watch me fail… repeatedly? Because this is Ten Tries.

Try 1

I printed an Among Us character from Thingiverse and attached it to a sprue with some hot glue. Then, I followed my process from Try Ten of my lost PLA casting project with one modification. I added some fiberglass cut to about ¼in lengths to the dry portion of the investment plaster mix. As usual, I grabbed a couple ingots of recycled pop cans to melt down.

After carefully inspecting the wreckage it looks like the cavities in the plaster formed perfectly. There was one big problem though; The plastic didn’t fully burn out of the plaster. If you saw my previous video, you know that I use graphite to indicate if the burnout worked properly. If there is graphite, at the end, the burnout failed. The gray color of the plaster should have let me know that the burnout wasn’t complete. I ignored this and some remaining plastic boiled on contact with the molten aluminum and broke the bottom of the plaster.

Try 2

I realized that there was charcoal remaining in the furnace from the last pour. This must have been the case for Try 1 as well. I use a few lumps of charcoal to remove the oxygen at higher furnace temperatures. This is great for protecting my heating element and aluminum from oxidation, but prevents plastic from burning completely if used too early in the process. This time, I was sure to remove the remaining charcoal before beginning the burnout.

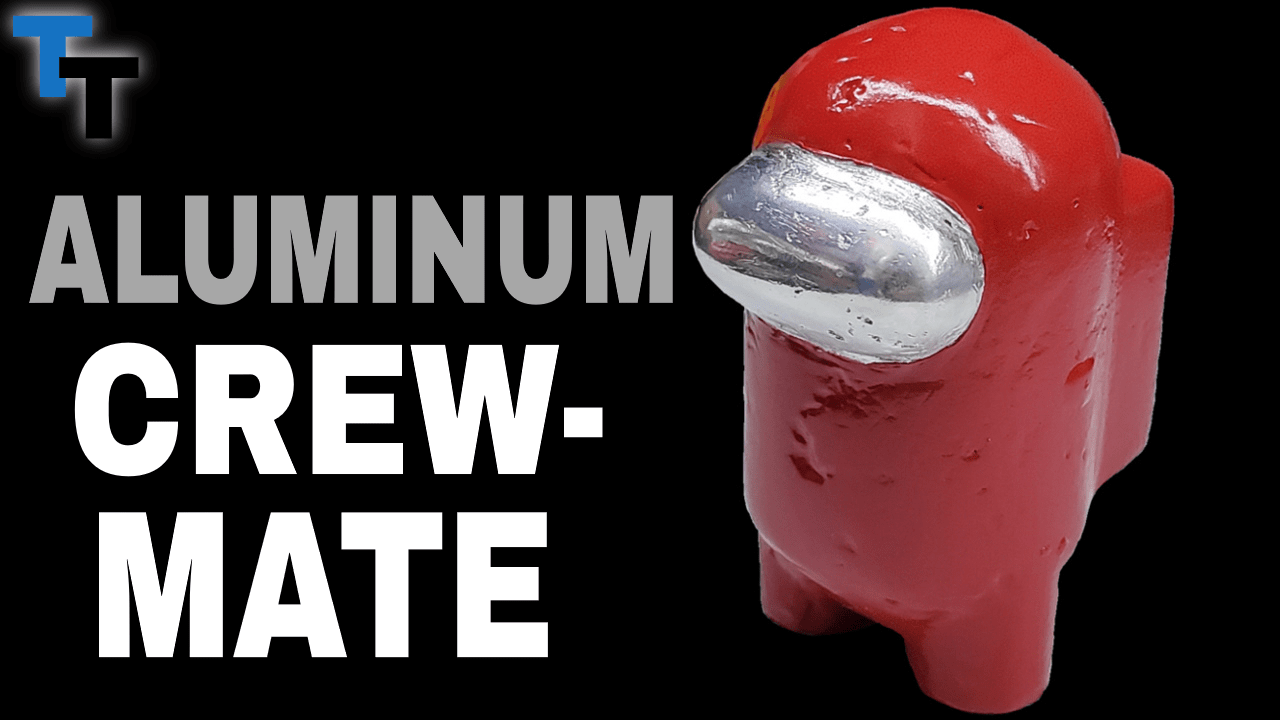

Wow! I’m amazed at how great the polished visor looks with the red suit!

This came out so well! What should I cast next? Let me know in the comments below!

Very cool!

Thanks!

I like how you got your fiance to do some of the tedious work!!

She volunteered! Guess she likes turning ugly stuff into pretty stuff!