Don’t buy crucible tongs before watching this video! A lot of options on the market can be flimsy and dangerous for you and your project. Check this out to see how I made these tongs.

Crucible tongs can be designed in many different ways. It’s very important to pick a design based on the crucible that you would like to use. They have to be sturdy to provide a safe grip and smooth pour. I picked sturdy tong designs that can cradle a #3 or #4 crucible safely and comfortably. Plus, they can be made in an afternoon from ordinary mild steel flat bar stock!

MATERIALS

Flat bar mild steel, 1-1/4in X 1/4in X 16ft – Your Local Steel Fabricator (much cheaper, should only be ~$20 for all of it), Amazon (need qty. 4 minimum)

M8 Nut, Bolt, and Washers – Harbor Freight, Amazon

High Temperature Paint – Amazon

Primer – Amazon

Flat Black Paint (the good stuff) – Amazon

LIFTING TONGS FABRICATION

Let’s start with the Lifting Tongs Fabrication.

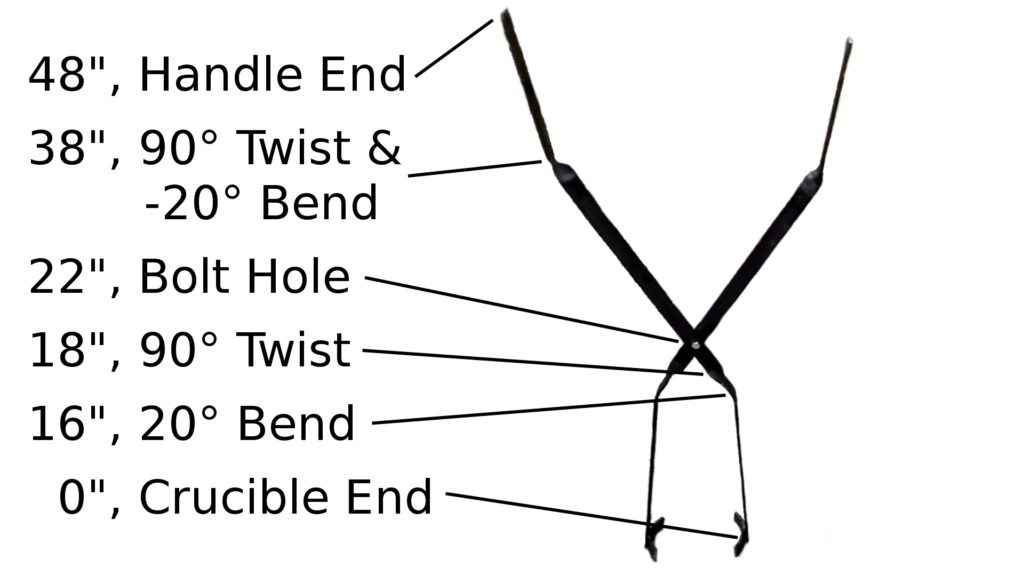

First, I cut a ¼” steel flatbar to 4 foot length. I base all of my measurements on the distance from the crucible end.

Then, we bend both to 20 degrees at 16 inches. Now we twist the flatbar to accommodate the pivot. To do that, we heat up the metal so it twists more easily. We put the piece on a bench vice and Twisted both at 18 inches.

Then, we twist both at 38 inches and bend to parallel with the other end.

We need some jaws to securely cradle the crucible. To make the “C” shape, we are using a hammer and anvil. We cut the curved metal piece at 6 inches.

Crucibles are fragile, and should be treated like glass. So, the sharp edges of the Jaws shouldn’t touch the crucible. We round the corners of the jaws with a bench grinder. This is an important step for protecting the crucible.

Jaws are done, now we weld them to the tongs making sure that we clean up any weld spatter that could damage the crucible. The tongs should pivot like a scissor. We drill a hole at 22 inches, and test fit the hinge bolt.

Looks good! Let’s build the pouring tongs.

POURING TONGS FABRICATION

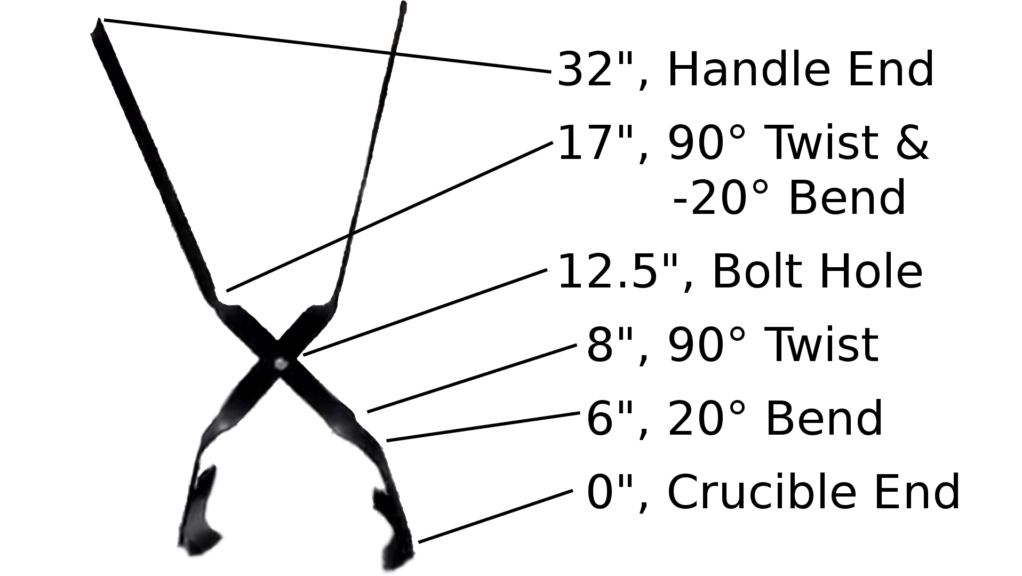

For the pouring tongs, we cut two 32 inch long pieces of ¼” steel flat bar and bend each to 20 degrees at 6 inches.

We twist both at 8 inches and then twist again at 17 inches and bend to parallel with the other end.

We form the jaws as before but this time weld the jaws parallel to the tongs.

To make it work like a tong, we drill a hole at 12.5 inches with 5/16” bit.

I test the fit M8 hinge bolt, you can find it at Harbor Freight.

PAINTING

The tongs work well. But to make them last, I paint them. When painting, proper surface preparation is key. I remove the rust with a wire wheel, so the paint will stick well.

Alright, primer time! I coat only the areas on the tongs that will NOT be exposed to high temperatures.

I use a washer hot glued to a bolt to keep overspray off the hinge contact patch. Then, I spray high temperature paint on parts of the tongs that may be exposed to high temperatures. After it dries, the high temperature paint needs to be cured at high temperatures. So, I put the tongs in a makeshift addition to my furnace and follow the curing instructions on the can. The insulation is rockwool that I got from Home Depot.

After curing, I add a coat of ordinary spray paint and let it cure forever if you buy cheap paint like I did or a couple days if you get the good stuff.

FINISHING TOUCHES

Alright, time for the finishing touches. I check if the bolt, nut, and washers are where they should be.

I put blue threadlocker on the bolts and nuts. I check the tightness of the joint. It should be tight enough so the joint doesn’t wobble but loose enough that the joint pivots freely. This will be difficult to fix after the threadlocker cures, so the bolt needs to be tightened properly now. I add some lubricant on the joints and I let the threadlocker cure for at least 24 hours before use.

As you can see, the lifting tongs work well! The pouring tongs also do a great job. They are sturdy and have a better quality than a lot of tongs on the market. Tell me in the comments section if there’s something that you would do differently or other foundry tools you find useful.

To see these tongs in action, check out this project next!

Could I buy a few pairs for my crucible? I really like how you heat treat them.

Thanks! We are currently developing a shippable design to sell online. Once they are complete, I’ll send you an email with a link to buy them!

I too would be interested in but a pair or two

Great! I’ll send you an email when we have some ready!

Would you ship to Australia

There’s a lot to figure out in regards to customs and tariffs. It may be some time down the road before we ship internationally.

Selling yet? Price?

Not yet, it’s a much larger undertaking to manufacture a new product at scale than I originally thought. With all the support, I certainly haven’t forgotten about it!