I came across a casting method by MyFordBoy that piqued my interest. It’s a combination of greensand casting and lost PLA. Basically, he prints a design in PLA, pours investment around it, burns out the PLA, and uses the investment mold as the sand casting cavity. I’m not sure that I’ve seen this method anywhere else, so that raised a couple questions. What’s the point and does it work at… whatever that point is? To best answer these questions, I tried it. Are you ready to watch me fail, repeatedly? Because this… is Ten Tries.

Kits:

Lost Wax (or Lost PLA) Lightweight Casting Powder 1.1

Before you spend all the time making it yourself, try out the pre-mixed casting plaster used in the Lost PLA Casting Project from Ten Tries!

The 5 lb kit that will make around 200 oz. (over 13 pints) of investment.

The kit includes 5, 10, or 15 lb of the pre-mixed powder. Just add water!

Lost PLA Mold Preparation

I 3D printed the parts I’d like to create. Then, I make a box of aluminum foil, packaging tape, and cardboard. I cover the edges with some silicone to seal the bottom and put a thin layer on the bottom of my 3D printed parts to glue them to the foil.

I pour some investment into the box I made and vibrate the bubbles out and let it cure for 24 hours and then remove the aluminum foil.

Before burning out the PLA, I make a tower with some stainless steel plates, stainless steel wire, and the blocks of investment.

Lost PLA Burnout and Greensand Casting Preparation

Now I put them inside the furnace. I programmed the temperature controller to heat up to 650 degrees celsius, hold at that temperature for 1 hour, and slowly return to room temperature. Normally, I would use my burnout schedule, but in MyFordBoy’s video, he just says he slowly increased the temperature to 650C. I made sure that the temperature did not increase or decrease faster than 2 degrees Celsius per minute.

As you can see, one of my blocks broke during the burnout. It looks like the temperature changes were too fast for the plaster, because it was too close to the heating element. I can do better next Try.

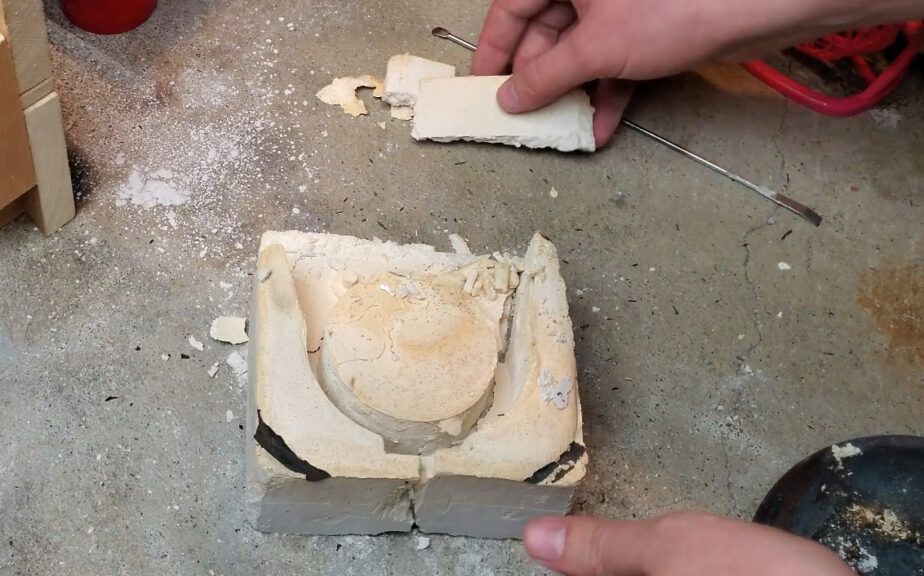

I remove the ash and other debris from inside the pattern, and then I prepare the cope and drag. One piece of the surviving block fell but I can drill the hole later.

The Result

I melt some aluminum and pour into the pouring basin.

Let’s check what we have now! It looks pretty good. The details are very impressive! Those layer lines are so clear and the corners are sharp!

Machining

Using my janky mini mill, I remove the gates, and sand a few small imperfections off of the parts. I also file down the rectangular cutout in the center of the die so that some flatbar steel can fit through. After four hours in the tumbler, they look pretty good!

Better than Greensand Casting

Why is this an improvement over greensand casting? Many shapes can be created that would simply fail if you tried to sand cast them. Without the proper draft angles, a pattern can’t be removed from the sand without damaging the cavity.

Better than Lost PLA

Why is this better than lost PLA? The sand allows the pouring basin to be much higher than the cavity without using more investment. This way, the aluminum fills the cavity at a higher pressure due to the weight of the aluminum above. Investment is expensive, so substituting reusable casting sand is a definite win.

Takeaway from MyFordBoy’s Greensand Casting/Lost PLA Method

I am a little surprised that someone as experienced at metal casting as MyFordBoy would say that a burnout is simply raising the temperature slowly to 650C. Really, you should follow the investment manufacturer’s burnout schedule or at least a burnout schedule of a similar investment formula. Maybe I’m nitpicking here, because a little bit of investment mixing in the sand likely isn’t a big issue. And I’m certain I’ve made my own mistakes while explaining things on… well… lots of things.

So, am I going to start Lost PLA Sand Casting Everything I make? No. I have to give it to MyFordBoy, this is a useful process for larger cast parts that have odd design elements that can’t be sandcast.

Check back soon for Try 2 and what contraption I’m making with these parts.